Vertical Integration

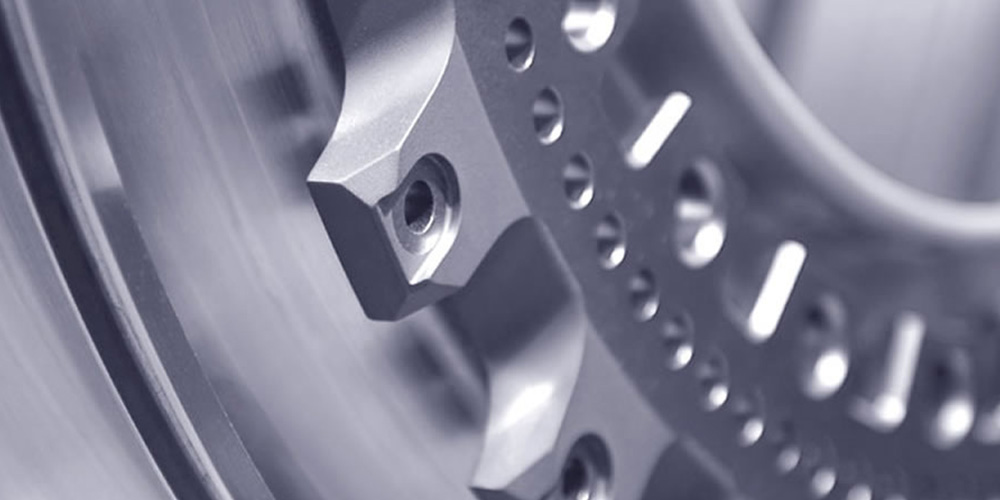

SinCo participates in automation planning and implementation. SinCo employs robotics in our lines to accomplish reduction of manpower, increased productivity and achieving quality and precision standards. Clients can be assured of lower material costs as physical handling is minimized under this supply chain.

Nascent Vertical Integration is a business strategy to produce everything from within the company’s supply chain. To increase our competitiveness, vertical integration allows us to combine multiple manufacturing processes to one stop. Moreover, with SinCo’s “downstream” manufacturing facility, coordination of production and inventory delivery scheduling will be greatly improved.

Our post processes include

- De-flashing

- Metal & plastic machining

- Lapping

- Magnetic de-burring

- Metal & plastic polishing

- Sand-blasting

- Laser etching

- Brushing

- Laser welding & riveting

Our decorative processes include

- Spray painting

- Color mixing

- Silk-screen printing

- Laser marking

- Hot stamping

- NCVM

- Anodizing